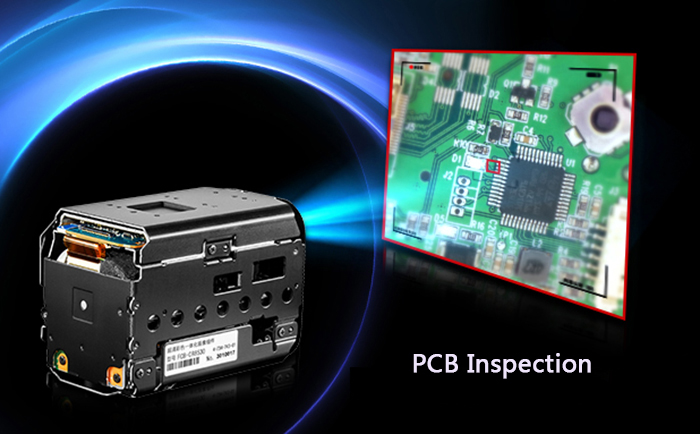

SONY FCB-ER8530, as SONY 4K ultra HD integrated camera modules, have shown excellent performance and broad application prospects in the field of PCB (printed circuit board) inspection. It can meet the requirements of different detection scenarios and provide accurate, clear and stable image quality, thereby improving detection efficiency and accuracy.

With the rapid development of science and technology, the design and production of printed circuit boards (PCB) are moving towards higher density, smaller line width and more complex layout. This trend not only greatly improves the performance and function of electronic products, but also poses unprecedented challenges to PCB inspection technology, especially visual inspection technology that relies on cameras.

Challenge analysis

1. high resolution requirements:

The increasingly small circuit wiring on PCBS means that inspection cameras need to have higher resolution to clearly capture and identify micrometer or even nanoscale line details. This puts forward higher requirements for camera sensor technology, lens design and image processing algorithm.

2. complex lighting environment:

PCB surfaces may contain a variety of materials and colors, and the characteristics of reflecting and absorbing light under different lighting conditions vary. The camera needs to obtain clear and accurate image information in different light environments such as low illumination, light and dark coexistence.

3. high color restoration requirements:

Various colors on the PCB board, including the color of the line, the color of the solder joint, and the color of possible defects (such as oxidation, burning, etc.). This requires the camera to have a high degree of color reproduction, that is, under different lighting conditions, the image color should remain stable.

The color difference between the image color taken by the camera and the actual color of the PCB board should be as small as possible. The control of chromatic aberration is essential to detect small defects on the PCB board, as even a small chromatic aberration can indicate a potential quality problem.

4. non-destructive amplification capacity:

The lines, solder joints, components, etc. on the PCB board can be very small and require the camera to have sufficient optical zoom capability to zoom in on these details for accurate detection. Optical zoom is able to provide greater magnification without loss of image quality, which is crucial for detecting small defects on PCB boards.

In PCB inspection, in addition to the need to enlarge the details, it is also necessary to maintain a certain field of view in order to conduct a comprehensive inspection of the entire PCB board. Therefore, the optical zoom capability of the camera needs to provide sufficient magnification to meet the needs of detection accuracy while maintaining the field of view.

Application advantage

1. advanced sensor:

Advanced sensor technology, such as CMOS or CCD sensors, enhances image quality by increasing pixel density and sensitivity. SONY FCB-ER8530 use 1/2.5 Exmor R CMOS sensors, effective pixels of about 8.51 million, can capture rich image details, even the PCB’s tiny flaws, can be accurately captured and clearly presented.

SONY’s Exmor R CMOS sensors are known for their high sensitivity and low noise performance. By optimizing pixel structure and signal processing, the SONY FCB-ER8530 capture more detail in low-light environments while reducing noise.

Combined with the high dynamic wide dynamic and high highlight suppression function, the SONY FCB-ER8530 can also cope with the complex bright light environment of PCB detection. This results in a clearer, more detailed image.

2. high resolution zoom lens:

High resolution lens is used to ensure that the image is not distorted during transmission. The SONY FCB-ER8530 support 4K ultra HD resolution of 3840×2160. With four times the number of pixels compared to traditional high definition (HD) resolution, 4K ensures that extremely clear, delicate images are captured during PCB inspection, helping to detect minute details and potential problems.

By adjusting the lens zoom, the 20x optical zoom capability of the SONY FCB-ER8530 makes it easy to zoom in on specific areas of the PCB without sacrificing image quality to capture more detail. This provides greater flexibility for inspecting both near and far size defects on the PCB board.

When the 20x optical zoom is combined with high resolution, the FCB-ER8530 are able to deliver superior image results in PCB inspection. The high resolution ensures that every detail in the image is clearly presented, while optical zoom allows PCB inspection to zoom in and out of the image without sacrificing picture quality. This combination makes FCB-ER8530 have a wide range of application prospects in PCB inspection.

3. Other functions and features

The SONY FCB-ER8530, thanks to advanced hardware composition, give them superior performance:

Fast and accurate automatic focusing, not only can be adjusted quickly according to different scenes, but also in the zoom process will not appear instant blur, flash screen and other phenomena, the picture always remains clear, greatly improving the quality and efficiency of PCB detection.

True color reproduction plays an irreplaceable role in PCB testing, which can improve detection accuracy, ensure product quality, improve detection efficiency, etc., and this excellent performance is more important in print testing.

4. integrated solutions

SONY FCB-ER8530 support connecting 4K-HDMI coding control board through LVDS to output 4K HDMI ultra-high-definition video signals, plug and play, without any setup of the camera. At the same time, it also supports 485 control and English OSD menu, convenient for users to zoom, focus, power off memory, preset bit and automatic cruise and other operations. These convenient connectivity and control features make the FCB-ER8530 easier to integrate and use in the field of PCB inspection.

5. Upgrade path:

In PCB detection, for scenes that need to move frequently or change rapidly, you can choose SONY’s latest 4K/60FPS integrated camera module FCB-ER9500, which has 4K ultra-high-definition resolution, 60 frames per second capture ability and 25 times optical zoom, even in high-speed moving or rapidly changing PCB detection scenes. Still able to maintain the clarity and fluidity of the picture.

To sum up, the SONY FCB-ER8530, with their outstanding technical performance, integrated solutions and upgrade paths, can play a full role in the field of PCB inspection. It can not only meet the challenging requirements of PCB inspection in different scenarios, provide accurate, clear and stable image quality, but also help users achieve more efficient and accurate PCB inspection and analysis, improve production quality and efficiency.

Sony FCB camera block

Sony FCB camera block