In the petroleum industry, pipeline inspection is a vital task, which is directly related to the safe transmission of energy and environmental protection. In this process, the improvement of inspection efficiency is of great significance for reducing costs, improving safety, and discovering and solving problems in time. SONY ILX-LR1 professional inspection camera, with its excellent performance and innovative technology, has helped the oil pipeline industry significantly improve inspection efficiency in many aspects.

1. Lightweight

In the process of oil pipeline inspection, UAV equipped with professional cameras has become an efficient and safe inspection method. Uav inspection can not only overcome difficulties such as complex terrain, long distance and harsh environment, but also significantly improve the efficiency and accuracy of inspection.

SONY ILX-LR1 professional inspection camera body weight only about 243 grams, compared to the traditional camera significantly reduced burden. This feature is particularly important for platforms such as drones that need to fly for long periods of time and maintain stability, as it can significantly reduce energy consumption during flight, extend endurance, and reduce flight instability due to increased weight.

With a size of approximately 100 x 74 x 42.5mm, the SONY ILX-LR1 can be easily integrated into a variety of miniaturized and sophisticated devices, such as drones, inspection robots, and even handheld stabilizers. Not only improves the overall beauty of the equipment, but also optimizes the space utilization rate, reduces the overall weight and load pressure of the equipment, and improves the endurance time of the UAV, thus effectively improving the work efficiency.

2. Highly integrated

The SONY ILX-LR1 professional inspection camera has M3 screw holes on all six sides and can be installed in various positions on drones, industrial equipment, robots or submersibles. In addition, it also has a 1/4-20 UNC screw hole at the bottom, with USB Type-C and Micro HDMI interfaces on the back, and its versatile interface and installation options greatly expand its application potential in various inspection scenarios, effectively improving the installation rate and further ensuring the shooting quality.

3. High quality imaging

The SONY ILX-LR1 professional inspection camera is equipped with a 35mm full-frame backlit Exmor R™ CMOS image sensor of approximately 61 million effective pixels, which enables the ILX-LR1 camera to capture extremely minute details of the oil pipeline and its surroundings. This is very helpful in finding potential problems such as tiny cracks, corrosion and leakage points on the surface of oil pipelines.

In terms of image quality is far beyond the previous camera equipment, shooting a photo after magnification can obtain details, in the previous may need to shoot more than 3 photos. At the same time, in terms of remote refined control of the equipment, the ILX-LR1 work efficiency is also better than before, the response time of taking a photo is close to 2 seconds, and the ILX-LR1 takes only about 1 second to take 3 photos, which greatly improves the flight speed and inspection efficiency of the UAV.

4. high-performance automatic focusing

For the oil pipeline inspection industry, it is very important to ensure the effectiveness of shooting materials, which is directly related to the accuracy of inspection results and the reliability of follow-up processing. Auto focus plays a great role in real-time remote shooting. The focus function of SONY ILX-LR1 can be accurate to 0.1 meters, compared with the previous half meter to 1 meter, and the image quality has been significantly improved, thus improving the inspection efficiency of oil pipelines.

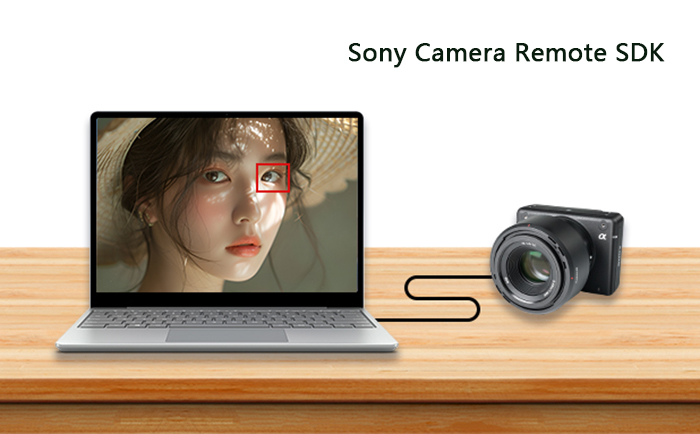

5. Remote SDK control

In addition, SONY ILX-LR1 SDK also opens a lot of interfaces, not only to achieve exposure, photography, shutter adjustment and other conventional functions, but also to achieve focus control, focus area control and other detailed regulation. For example, in the process of oil pipeline inspection, the camera can measure the distance between the drone and the pipeline, and complete the focus through this shooting distance, providing more perfect and accurate photography function. This greatly improves the flexibility and efficiency of inspection.

6. DC power supply

In terms of electrical performance, SONY ILX-LR1 professional inspection camera also has significant changes, its body is equipped with DC power supply port, which can support DC power supply to ensure the endurance and stability of flight work. It can significantly extend the working time of the camera and reduce the interruption of inspection due to battery replacement, thus improving the continuity and efficiency of inspection work.

In summary, the SONY ILX-LR1 professional inspection camera, with its unique combination of advantages, can improve the efficiency of oil pipeline inspection by about 30%. It has shown strong application potential and value in the field of oil pipeline inspection, and has made important contributions to ensuring energy safety transmission and environmental protection.

Sony FCB camera block

Sony FCB camera block