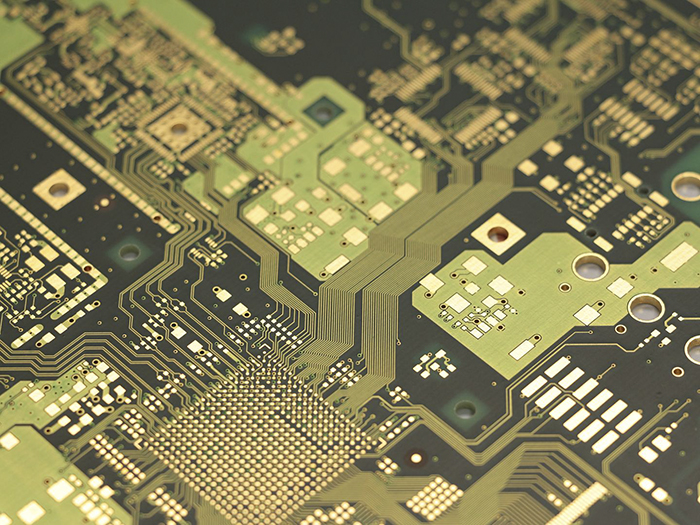

In the field of PCB (Printed Circuit Board, printed circuit board) detection, the accurate capture of details and the overall macro control is the key to ensure product quality. As a high-performance industrial camera, the SONY FCB-EW9500H, with its superior imaging technology and comprehensive features, perfectly meets the full range of PCB inspection needs from the details to the global.

High-performance support

First, high definition imaging

The FCB-EW9500H uses a 4-megapixel image sensor and a high-resolution lens to ensure excellent clarity. In PCB inspection, high-definition imaging is crucial because it is able to capture tiny details and defects on the board, such as line breaks, short circuits, component misalignments, and so on. These details are essential to ensure the quality and reliability of the PCB.

Second, high sensitivity

By using the new pixel unit structure and circuit technology, the FCB-EW9500H effectively improves the efficiency of light utilization and achieves higher sensitivity than traditional image sensor products. In the PCB inspection process, it is sometimes necessary to carry out in a low-light environment, such as the inspection inside the circuit board or night work. The high sensitivity of the FCB-EW9500H ensures that clear images can be captured even in low light environments, improving the accuracy and efficiency of inspection.

Three, fast automatic focusing

The application of fast autofocus in the PCB inspection industry is mainly reflected in improving the inspection efficiency, ensuring the detection accuracy and adapting to the complex inspection environment. It can effectively improve the detection efficiency.

Instant focus: The SONY FCB-EW9500H fast autofocus technology can complete the focusing process in a very short time without human intervention, which greatly reduces the detection cycle. For high-volume, high-efficiency PCB production lines, this means that the detection speed can be significantly improved and the waiting time can be reduced.

Continuous inspection: In the PCB inspection process, because the circuit board may have ups and downs or components of different heights, the traditional manual focusing method is difficult to meet the needs of continuous and rapid detection. The SONY FCB-EW9500H Fast Autofocus technology can automatically adjust the focal length to ensure that clear images can be obtained on components at different heights and positions for continuous and uninterrupted inspection.

Four, excellent image stability

The FCB-EW9500H uses super image stabilization technology. Through greatly improved blur suppression and image stabilization technology, it can effectively reduce image blur and obtain very accurate video even in the environment with violent shake. In PCB inspection, small vibrations of detection equipment (such as robotic arms, automated inspection tables, etc.) may have an impact on image quality. The image stabilization technology of the FCB-EW9500H ensures stable images in these environments, improving the accuracy and reliability of detection.

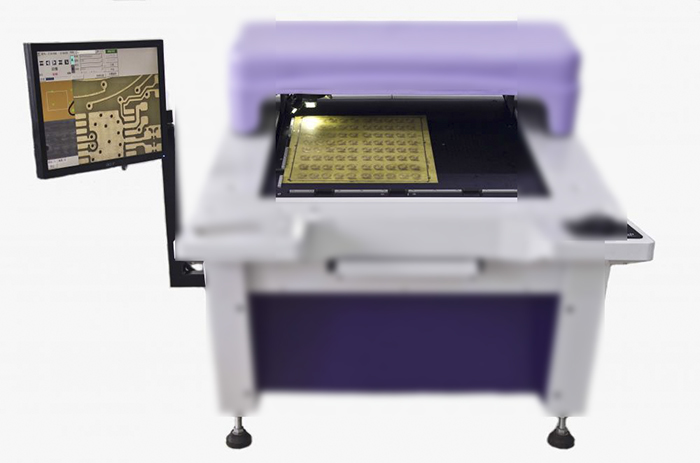

Five, integrated composition, small size, low cost

The SONY FCB-EW9500H integrated camera module integrates key components such as lenses, image sensors, and image processing chips in a compact housing, greatly reducing the need for external connection and assembly, thereby reducing overall volume and cost.

Practical application case

Although the specific PCB inspection application case may vary depending on the industry, equipment and inspection requirements, the FCB-EW9500H has a wide range of application prospects in the field of PCB inspection with its excellent performance characteristics. For example, in the automated PCB inspection line, the FCB-EW9500H can be used as a key image acquisition device, in conjunction with automatic equipment such as image processing software and robotic arms, to achieve fast and accurate PCB inspection.

In summary, the practical application of SONY FCB-EW9500H in PCB inspection is mainly reflected in its high definition imaging, high sensitivity, fast autofocus and excellent image stability. These characteristics make the FCB-EW9500H ideal for PCB inspection, helping to improve the accuracy and efficiency of inspection.

Sony FCB camera block

Sony FCB camera block